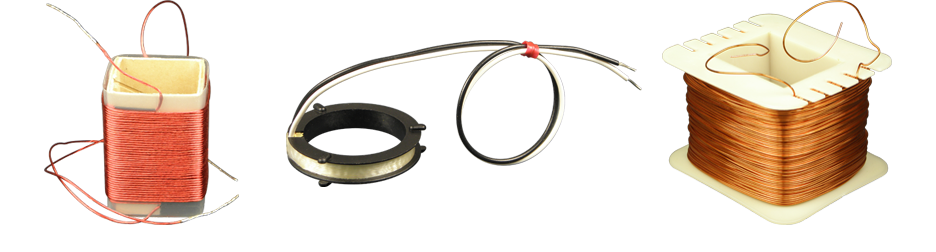

Custom Coil Design

Custom Magnetics, Inc.'s coil design and manufacturing service has the experience, knowledge, resources, and equipment to provide you with custom wound electrical coils that fit your individual application requirements. Options are numerous and combinations are almost limitless, enabling us to provide you with the exact coil for any or all of your electrical equipment manufacturing needs.

We offer both bobbin or self-supporting coils, Litz, and nylon served Litz wires from 47 AWG and up. Coils are available in square, rectangular, round, oval, or other custom shapes with fly leads, PCB pins, solder terminals, or screw terminals. Coil form materials include paper tube, many types of nylon, glass filled nylon, as well as LCP and other materials upon request. Our computer controlled equipment is capable of single-, multi- and random layer, as well as precision and dry winding processes, and finishing options include varnish impregnating, molding, and potting.

Our advanced technical and manufacturing expertise combined with our commitment to quality makes us a top choice for all of your custom coil requirements. We respond quickly to customer demands and offer very competitive pricing and short lead times. To learn more about our custom coil design and manufacturing services, contact us today.