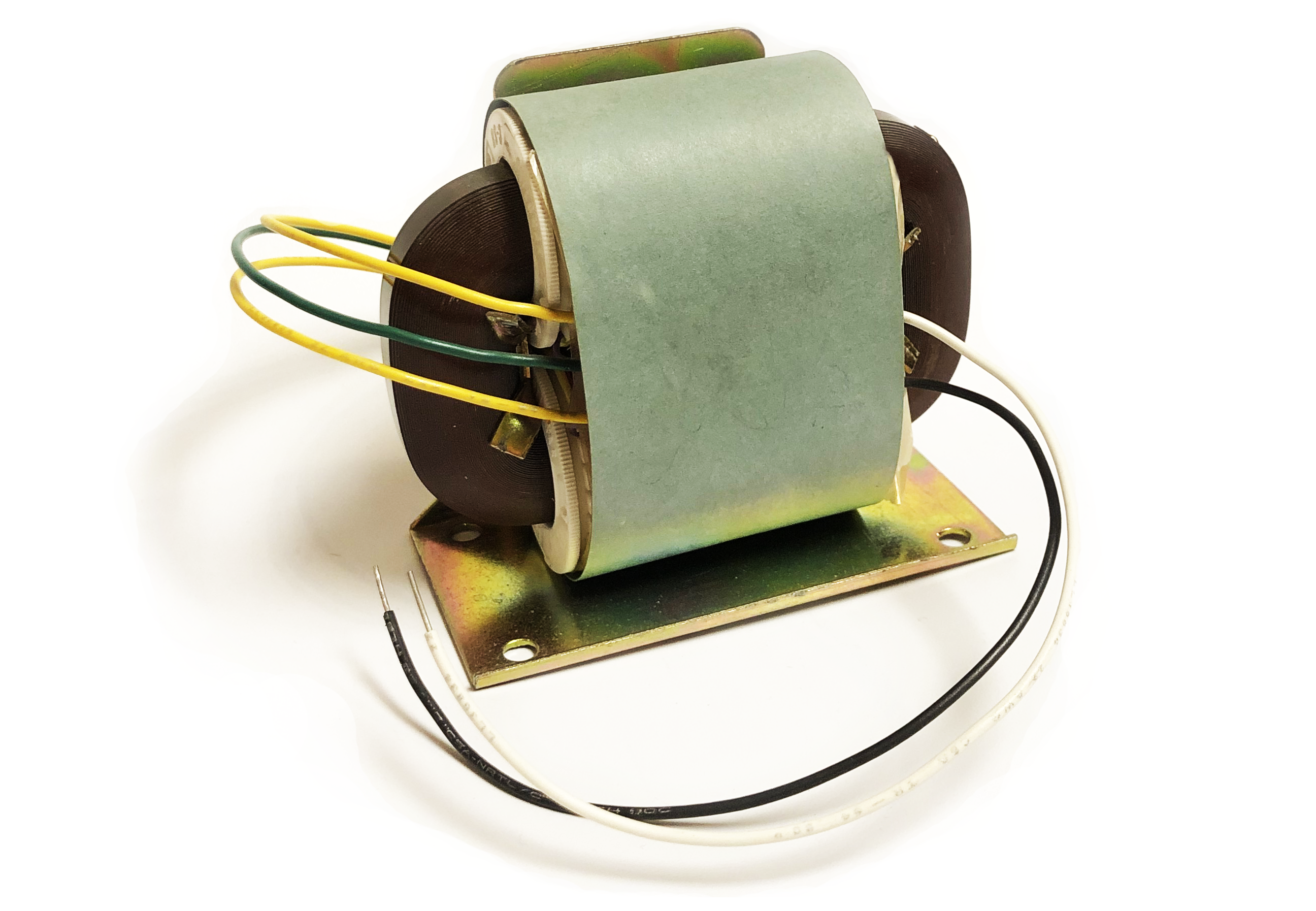

R-Core Transformers

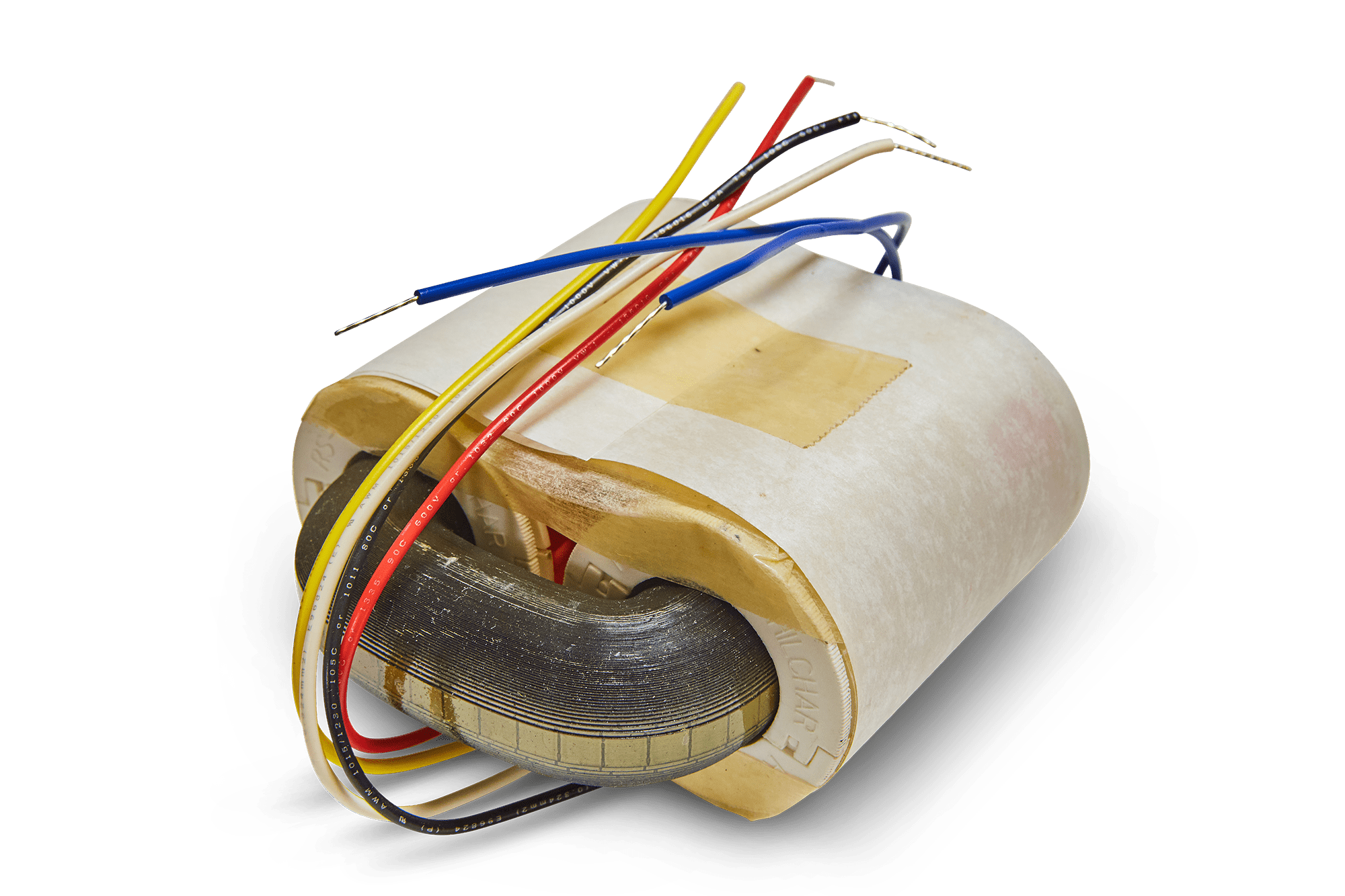

R-Core Transformers are manufactured using a unique rectangular core with a round cross section known as an R-Core. These special cores, developed by Japanese engineers, feature a continuous strip of grain-oriented silicon steel with no air-gap. The winding is done on special round bobbins on the two parallel legs of the core.

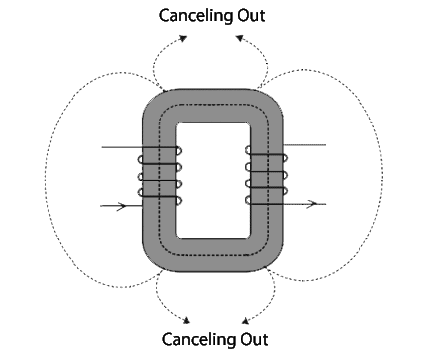

R-Core Transformers can be designed so that coil windings mutually cancel each other's magnetic flux by means of balanced, symmetrical winding on the two legs. With this winding method the leakage flux can be kept to a minimum.

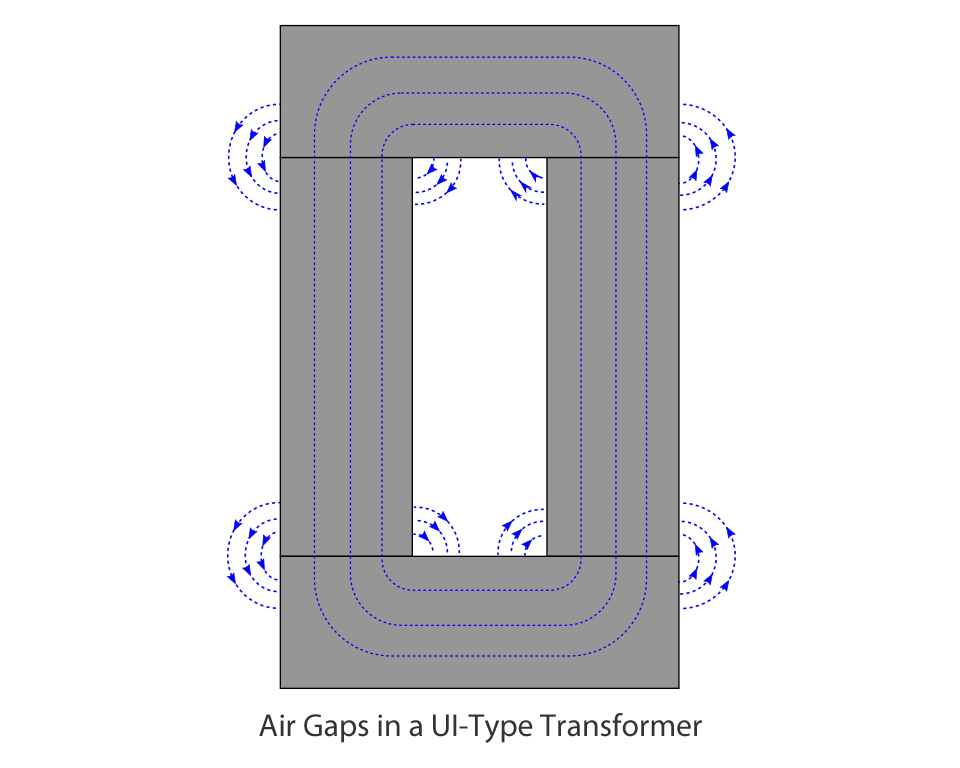

Additionally R-Core transformers have absolutely no gap in the magnetic path. Again this feature allows leakage flux to be extremely low. EI-type, UI-type, and cut core type transformers have 2 to 6 magnetic gaps. A great deal of leakage flux escapes from these magnetic gaps. In fact, leakage flux in an R-Core Transformer is about 1/10th that of conventional EI or UI transformers.

The R-Core with its low-leakage, low-noise characteristics is well suited for medical equipment, audio & video amplifiers, and other noise sensitive equipment. Circuit designers are able to place the transformer closer to other critical electronic components.

Another unique feature of the R-Core is the use of two part bobbins. The primary winding and secondary winding are done on separate concentric bobbins thus ensuring complete isolation. This allows meeting of any safety standards requirement.

| Characteristic | R-Core | Toroidal | EI Type |

|---|---|---|---|

| Leakage Flux | With balanced winding canceling the leakage flux, the total amount of leakage flux is extremely small. As a result can be used even without shield. | While there are no gaps in the magnetic path, the winding are not balanced hence there is still some leakage flux. Shielding is often required to reduce the effect on other components. | There are gaps in the magnetic path and the winding is not balanced. As a result the leakage flux is very high which can affect sensitive electronic components if proper shielding is not provided. |

| Winding | Winding is done on special machine resulting in evenly spaced winding. Balanced winding is an inherent constituent of the design. | The winding is not evenly spaced. The density of turns on the inner edge is more and on the outer edge the wires are roughly spaced out. Thus the winding is not balanced. | While the layers of turns are well laid out the winding is only on the center limb of the EI core. Thus it is not balanced. |

| Exciting Current | The exciting current is minimal as all the magnetic paths are in alignment with the rolling direction of the steel and there is no gap in the core. | The exciting current is less than that in EI Transformers, but generally higher than that of R-Core transformers due to lack of balancing of windings. | More exciting current is required due to presence of magnetic gaps, the inability to use the effect of rolling direction of grain oriented steel, the variation in assembly operation, etc. |

| Efficiency | Very low losses result in better efficiency. Efficiency of greater than 90% is generally observed in most designs. | Efficiency is better than EI Transformer but generally less than an R-Core transformer. | More losses result in poor efficiency. |

| Mounting | Due to inherently thin design & light weight, the R-Core Transformers can be mounted in several ways. It can be mounted flat, vertically, or on the its side. | Because of the circular shape mounting options are limited. | Due to its cubic shape and heavier weight, the EI Transformer generally takes up more space in the assembly. |